Lab. Automation & Microarrayer

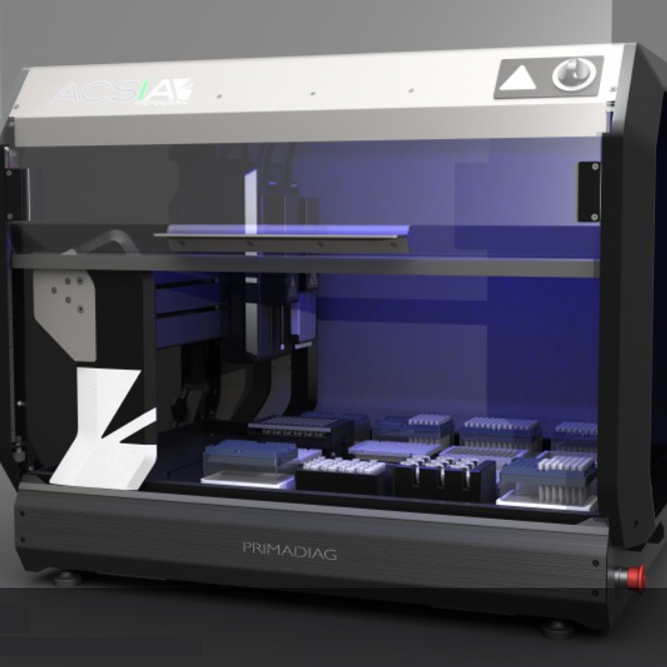

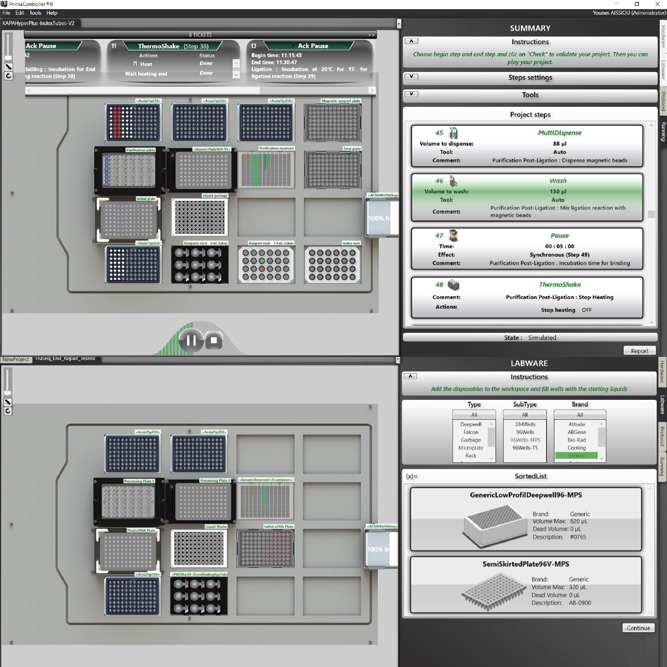

The ACSIA Line from Primadiag(www.primadiag.com), is the innovative automation solution bringing quality, cost efficiency and simplicity to all the genomics (specifically NGS) and proteomics laboratories. The ACSIA product line is designed as the best value for money to perform a wide variety of liquid handling protocols with the lowest effort from the end user. It offers a mastered cost for a fast return on investment.

Products Info

Project Description

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed tempus nibh sed elimttis adipiscing. Fusce in hendrerit purus. Suspendisse potenti. Proin quis eros odio, dapibus dictum mauris. Donec nisi libero, adipiscing id pretium eget, consectetur sit amet leo. Nam at eros quis mi egestas fringilla non nec purus.

Live Preview-

Skills

-

Client

Okler Themes

Project Description

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed tempus nibh sed elimttis adipiscing. Fusce in hendrerit purus. Suspendisse potenti. Proin quis eros odio, dapibus dictum mauris. Donec nisi libero, adipiscing id pretium eget, consectetur sit amet leo. Nam at eros quis mi egestas fringilla non nec purus.

Live Preview-

Skills

-

Client

Okler Themes

Project Description

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed tempus nibh sed elimttis adipiscing. Fusce in hendrerit purus. Suspendisse potenti. Proin quis eros odio, dapibus dictum mauris. Donec nisi libero, adipiscing id pretium eget, consectetur sit amet leo. Nam at eros quis mi egestas fringilla non nec purus.

Live Preview-

Skills

-

Client

Okler Themes

Project Description

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed tempus nibh sed elimttis adipiscing. Fusce in hendrerit purus. Suspendisse potenti. Proin quis eros odio, dapibus dictum mauris. Donec nisi libero, adipiscing id pretium eget, consectetur sit amet leo. Nam at eros quis mi egestas fringilla non nec purus.

Live Preview-

Skills

-

Client

Okler Themes

The ACSIA Line from PrimaDiag, ACSIA is the largest of our platforms. With 16 SBS positions, it allows to perform complex protocols by adding numerous modules to its workspace like shakers, thermoregulated modules or magnetic work units. ACSIA XS is the most compact of our platforms with 8 SBS positions and its 3 XS racks for tubes. It can integrate one 1- or one 8- channels pipette to process a wide variety of protocols of liquid handling.

| ACSIA | ACSIA XS | |

|---|---|---|

| Size LxDxH |

100x72x75cm | 78x72x75cm |

| No of Position for SBS plate or others |

16 Positions | 8 Positions |

| Main Application | High efficient PCR/qPCR High efficient Clean-up NGS library NGS target enrichment |

Compact PCR/qPCR Compact Clean-up |

| Custom Protocol | >Yes | >Yes |

| Software | PrimaControllerII | PrimaControllerII |

How to choose your edition?

For each of your need, PrimaDiag intends to respond by tuning your configuration in four steps:

1. Analyze and define the application

2. Choose the adapted platform

3. Determine and integrate the suitable accessories

4. Write and optimize your protocols on your specific configuration

| Application(Needs) | ACSIA PCR Edition | ACSIA Clean-up Edition | ACSIA NGS Edition |

|---|---|---|---|

| General pipetting tasks | |||

| Distribution | V | V | V |

| Tube to plate transfer | V | V | V |

| Plate to plate transfer | V | V | V |

| Serial dilutions | V | V | V |

| Hit picking | V | V | V |

| Concentration normalization | V | V | V |

| Plate compression/decompression | V | V | V |

| Genomics | |||

| PCR Setup in 96 and 384-well plate | V | V | V |

| Real ime PCR Setup in 96 and 384-well plate | V | V | V |

| SNP detection | V | V | V |

| HLA genotyping | V | V | V |

| Forensics | V | V | |

| Sequencing setup | V | V | |

| Nucleic Acid purification | |||

| PCR and sequencing clean-up | V | V | |

| gDNA from various matrixes | V | V | |

| Plasmid preparation | V | V | |

| Next Generation Sequencing | |||

| Library preparation for NGS | V | ||

| Enrichment for NGS | V | ||

| Proteins | |||

| Sample preparation for LC-MS/MS analysis | V | V | |

| Cloning & Synthetic biology | |||

| Gibson Assembly cloning | V |

Product Moving Pictures

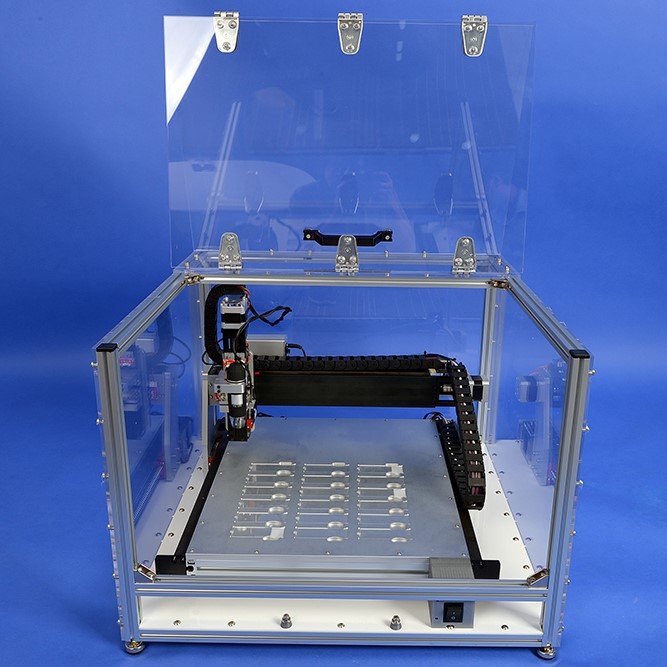

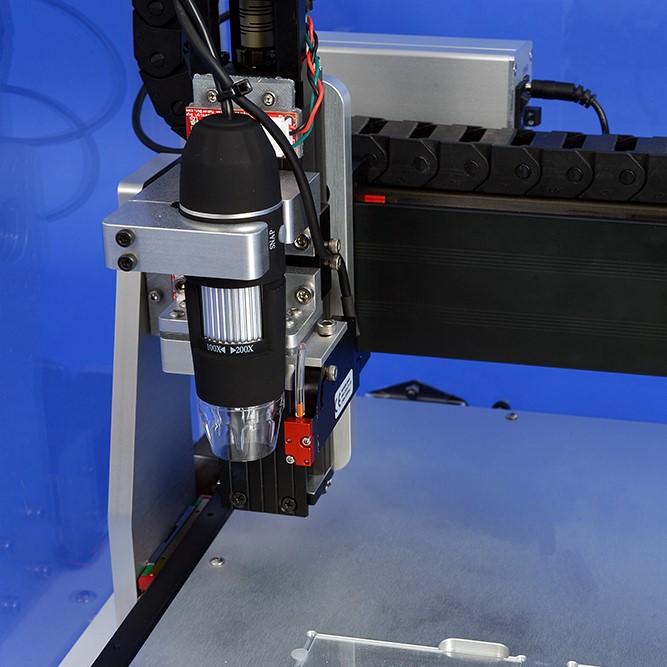

BioSpot® Worksations from Biofluidix(www.biofluidix.com) are the perfect automation platform for your dispensing applications based on our single channel and microarray products and can be equipped to your needs with up to 12 dispensing channels as well as optical process control features.

Products Info

Project Description

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed tempus nibh sed elimttis adipiscing. Fusce in hendrerit purus. Suspendisse potenti. Proin quis eros odio, dapibus dictum mauris. Donec nisi libero, adipiscing id pretium eget, consectetur sit amet leo. Nam at eros quis mi egestas fringilla non nec purus.

Live Preview-

Skills

-

Client

Okler Themes

Project Description

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed tempus nibh sed elimttis adipiscing. Fusce in hendrerit purus. Suspendisse potenti. Proin quis eros odio, dapibus dictum mauris. Donec nisi libero, adipiscing id pretium eget, consectetur sit amet leo. Nam at eros quis mi egestas fringilla non nec purus.

Live Preview-

Skills

-

Client

Okler Themes

The BioSpot BT is by default equipped with our TopView and SmartDrop process control features. So, you don’t even have to manually set the dispensing parameters for your PipeJet NanoDispenser channels. The BioSpot BT will do that automatically for you. You only have to set your single droplet target volume in the software. With the TopView camera you can control the dispensing performance after processing your substrate. The pictures taken are stored and you can use them for internal process documentation and quality control.

| BioSpot BT 600 | BioSpot BT 750 | |

|---|---|---|

| Compatible Dispensers | SiJet PicoDispenser PipeJet NanoDispenser ValveJet MicroDispenser |

SiJet PicoDispenser PipeJet NanoDispenser ValveJet MicroDispenser |

| Max. number of dispensing channels |

12 channels | 12 channels |

| Asipration possible | Yes | Yes |

| Max. number of aspiration channelsl |

>8 channels | >8 channels |

| Max. addressable area | mm |

300 x 400 | 300 x 550 |

| Dimensions | cm (H x W x D) |

54 x 55 x 63 | 54 x 55 x 78 |

| Integrated SmartDrop TopView Camera |

Yes | Yes |

| Ingerated Electronics | Control ElectroniX 200 | Control ElectroniX 200 |

Your benefits

Product Features

Application

| Life Science | Industry |

|---|---|

| Printing of Lateral Flow Assays | Coating of medical products |

| Printing of microarrays | Printing of adhesives |

| Filling of microfluidic chips | Flux dispensing |

| Miniaturization of assays | Surface optimization |

Product Moving Pictures

OptiSpotTM Microarrayer is a piezoelectric non-contact microarrayer with optical camera that manufactures high quality biochips by spotting various kinds of biomaterials uniformly with micro-spot size on 25mm x 75mm substrate. The camera that allows to check the shape of the microarray substrate is equipped, allowing researchers to dispense the samples at the correct position after presetting spot points. (Up to 18 slides (25mm x 75mm) can be placed on the workstation.) High-quality DNA chips, protein chips and bio-chips can be produced by using OptiSpotTM Microarrayer.

Products Info

Project Description

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed tempus nibh sed elimttis adipiscing. Fusce in hendrerit purus. Suspendisse potenti. Proin quis eros odio, dapibus dictum mauris. Donec nisi libero, adipiscing id pretium eget, consectetur sit amet leo. Nam at eros quis mi egestas fringilla non nec purus.

Live Preview-

Skills

-

Client

Okler Themes

Project Description

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed tempus nibh sed elimttis adipiscing. Fusce in hendrerit purus. Suspendisse potenti. Proin quis eros odio, dapibus dictum mauris. Donec nisi libero, adipiscing id pretium eget, consectetur sit amet leo. Nam at eros quis mi egestas fringilla non nec purus.

Live Preview-

Skills

-

Client

Okler Themes

Product Features

System Configures

Product Moving Pictures

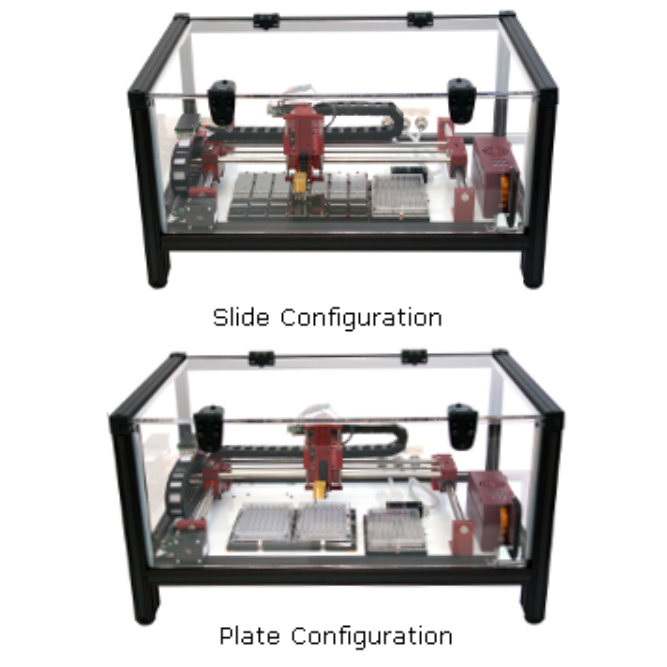

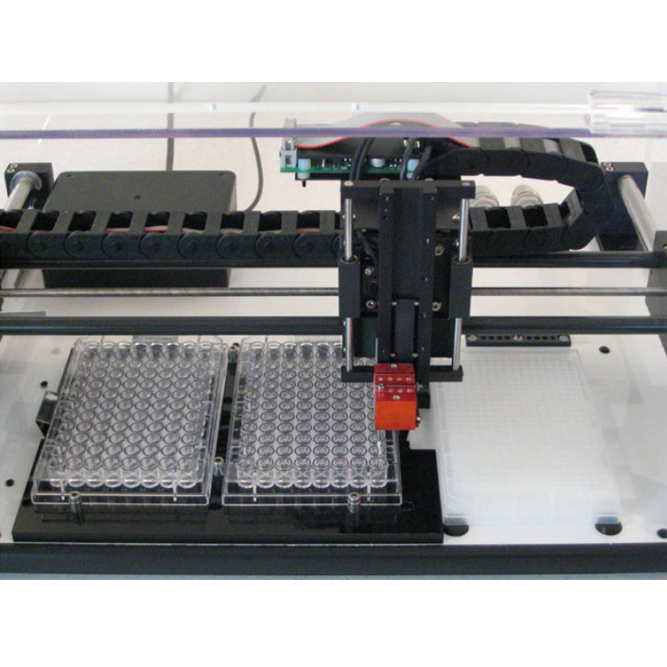

XactII microarrayer from LabNEXT(www.labnext.com) is a versatile instrument. It can be equipped for slide or plate printing. Changes in the configurations are done in the lab. The microarrayer software also allows using virtually unlimited variants of custom labware and substrates (custom holders needed). Xact microarrayer can use either LabNEXT Xtend or Xtend RM pins or pins from other vendors, giving options for selecting best deposition technology for a particular experiment.

Products Info

Project Description

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed tempus nibh sed elimttis adipiscing. Fusce in hendrerit purus. Suspendisse potenti. Proin quis eros odio, dapibus dictum mauris. Donec nisi libero, adipiscing id pretium eget, consectetur sit amet leo. Nam at eros quis mi egestas fringilla non nec purus.

Live Preview-

Skills

-

Client

Okler Themes

Project Description

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed tempus nibh sed elimttis adipiscing. Fusce in hendrerit purus. Suspendisse potenti. Proin quis eros odio, dapibus dictum mauris. Donec nisi libero, adipiscing id pretium eget, consectetur sit amet leo. Nam at eros quis mi egestas fringilla non nec purus.

Live Preview-

Skills

-

Client

Okler Themes